The Low Down on One-Ton Axle Swaps

We’re pretty stoked. Why, you ask? Because we got to sit down with Bob Corcoran to talk all about one-ton axle swaps. Bob’s newest build is a 2018 Jeep Wrangler JL Rubicon named Boblife365 with 40” tires and he recently swapped his stock axles for Dynatrac’s XD60/60 Combo one-tons and he laid it alllll out for us.

Now we know–there’s often times a heated debate around junkyard one-ton axle swaps vs. the higher-priced bolt on option and he’ll address both sides of the argument. So buckle up and let’s get down to one-ton axle business. Read our full interview with Bob Corcoran below.

First things first, why One Tons?

I went one ton because I’m running 40’’ tires. I’ve ran 40” tires for over a year now on a Jeep Wrangler JLU Rubicon.

The main reason I went with bigger and beefier axles on this new JL build is hands down the peace of mind that they provide when running a tire this big.

I’ve bent axle flanges multiple times on Dana 44 rear axles (four times to be exact: twice on my old Jeep and twice on my new Jeep). It’s very easy to bend an axle flange. Just hitting potholes doing daily driving with 40” tires, let alone jumping it through sand dunes and off rock faces and all over the spots around the country where I like to go wheeling can bend an axle flange.

The other big component (no pun intended) that goes into deciding whether or not you’re going to run one-ton axles is: it’s actually less wear and tear on driveline. So with one-ton axles, you get to use locking and unlocking front hubs. That means when I’m driving my Jeep (it’s also my daily driver), I’m able to make it so the front driveshaft, the front axle shaft and the front gears don’t even spin going down the road, which improves driveability a lot when you’re on 40” tires with that much rotating mass.

Overall, it improves longevity of the high-end aftermarket parts that I run. A typical driveshaft in the front can cost you $500 alone, and then you’ve got hubs and ball joints and all these other things that if they’re ALWAYS spinning, ALWAYS turning, ALWAYS having wear on them, those expensive parts can wear quickly if you’re daily driving your rig and pushing its limits routinely on and off-road.

How would a driver know their axle flanges are bent? Can you describe some of the symptoms?

The way you know if your rear axle flanges are bent is if you look at your rear tires and you’ve got a side-to-side movement, like a wobble almost, in your rear tire, chances are you’ve probably bent something in the rear. Or you hear a squeak from your rear brakes just driving through parking lots and not applying any pressure. It can be pretty easy to bend something because you’re running all this weight on this tiny little bearing on the axle shaft.

A typical 40” tire weighs 135 to 150 lbs, with the full beadlock set up and depending on what tire you’re going with, that’s a lot of weight to be running on stock parts like that.

Other things you would notice by running stock axles on 40” tires is the stock parts wear faster. Things like your steering starting to loosen up, brakes get squishy and in the worst case scenario something just breaks all together. These components are not meant to last forever but they are supposed to last a lot longer than what you would typically see when you’re running big tires. When you move up to one-ton axles, whether it be a ready-to-go bolt in set or a you’re building them from scratch, everything gets upgraded, and is now built to handle most anything.

What causes a weaker axle like a stock or smaller axle such as a 44 or 30 to fail?

Really small gears. When you move up to a one-ton axle, what you’re doing is increasing your ring gear size, your pinion gear size and you’re increasing your actual differential size overall, which is a HUGE benefit. Think of it like this: if you’ve ever taken two donut holes and stuck toothpicks in the middle of them and then held them with your fingers right there in the middle, that’s essentially what you’re doing when you’re running down the road with big tires and stock axles. Now take two pretzel rods and add some fondu…wait…wrong article. Essentially, you’ve got fewer splines on already small axle shafts that are going into small gears connecting to a small pinion and creating an immense amount of stress on those internal components.

Then we take that thing off road, all it takes is a little bit of torque the wrong way and you’ve just snapped everything in one shot.

It’s a big investment, correct?

Yes, it’s a huge investment or expense or need or want but more so a need 😉. For me, it has always been an end goal for my Jeep build. My last Jeep had a junkyard One-Ton swap consisting of a Superduty 60 Front and 14 Bolt Rear and I knew the day I bought the Jeep that I would wheel it hard, and once I got tired of breaking stock parts I would upgrade to big boy axles. If you’re someone that is going to go with one-ton axles, there is a list of things to consider, but most of all, consider your budget, the type of wheeling you will be doing, and always choose the highest quality of parts you can afford the FIRST time around. It’s that type of investment…or like I said, need or want (but mostly a need)!

What kind of resale value do you get on a set of Dana 44s off of a Rubicon?

So, the Rubicon 44s on a JK or JL, I’ve seen them range from $2,500 all the way up to $4,500 depending on how well they’re built because a lot of people also spend a lot of time and money using some other incredible aftermarket components to build up their stock axle housings.

What should a consumer look to spend on just the axles themselves for the upgrade?

Well, there is a lot of competition in the aftermarket axle world. It’s a tough question to answer subjectively because for around $13,000 you can go out and get yourself a set of Ultimate 60 Dana axles, the company that makes the same stock Dana 44 and Dana 30 axles underneath the Jeep or you can go to a company like Dynatrac or Teraflex, for example. I personally chose Dynatrac.

When you’re shopping for axles from a company like Dynatrac, prices can range from $12,000 to $18,000 depending on how you option them out or you go full custom and they can just build it to spec for your specific needs. So I guess, the best way to answer this question is rather than having an idea of “I need to spend this amount to get this,” it’s more like, what do you need parts wise out of your axles, what type of wheeling are you going to be doing and how are you going to build the perfect pair to meet your exact needs. When you start looking at it from that angle, you’ll start breaking things down and looking into the quality of the product:

- Is it all USA Made?

- How do the welds compare to others?

- What is the customer support like if I have an issue?

For me and my decision to choose Dynatrac, it was simple. The quality of the Dynatrac product and the people behind the brand are what make it the best choice hands down.

When you mix passionate off-road enthusiasts with heavy machinery and really well-done engineering, there is some seriously neat stuff that gets made!

Okay so, you’ve decided to do an axle swap. What components of your build do you have to change for fitment on your new axles?

Here’s the best part about making a one-ton axle swap: we live in a day and age where the technology used in fabrication and the ability to create aftermarket brackets that bolt directly to your Jeep is something you can simply go on the internet and decide to purchase. You can buy the artec industries one-ton swap kit or you can buy Dynatrac 100% ready-to-go bolt on axles. Both of these options are going to bolt up to stock stock brackets on the frame if you choose. You don’t have to cut a bunch of stuff off of your Jeep to install one-ton axles anymore. You don’t have to have some elaborate suspension set up. You simply need new driveshafts and you need a way to power your new lockers (whether it be electronic or air), make sure all the important bits like brake lines and calipers and the essentials all are functional and you can hit the road or the trail.

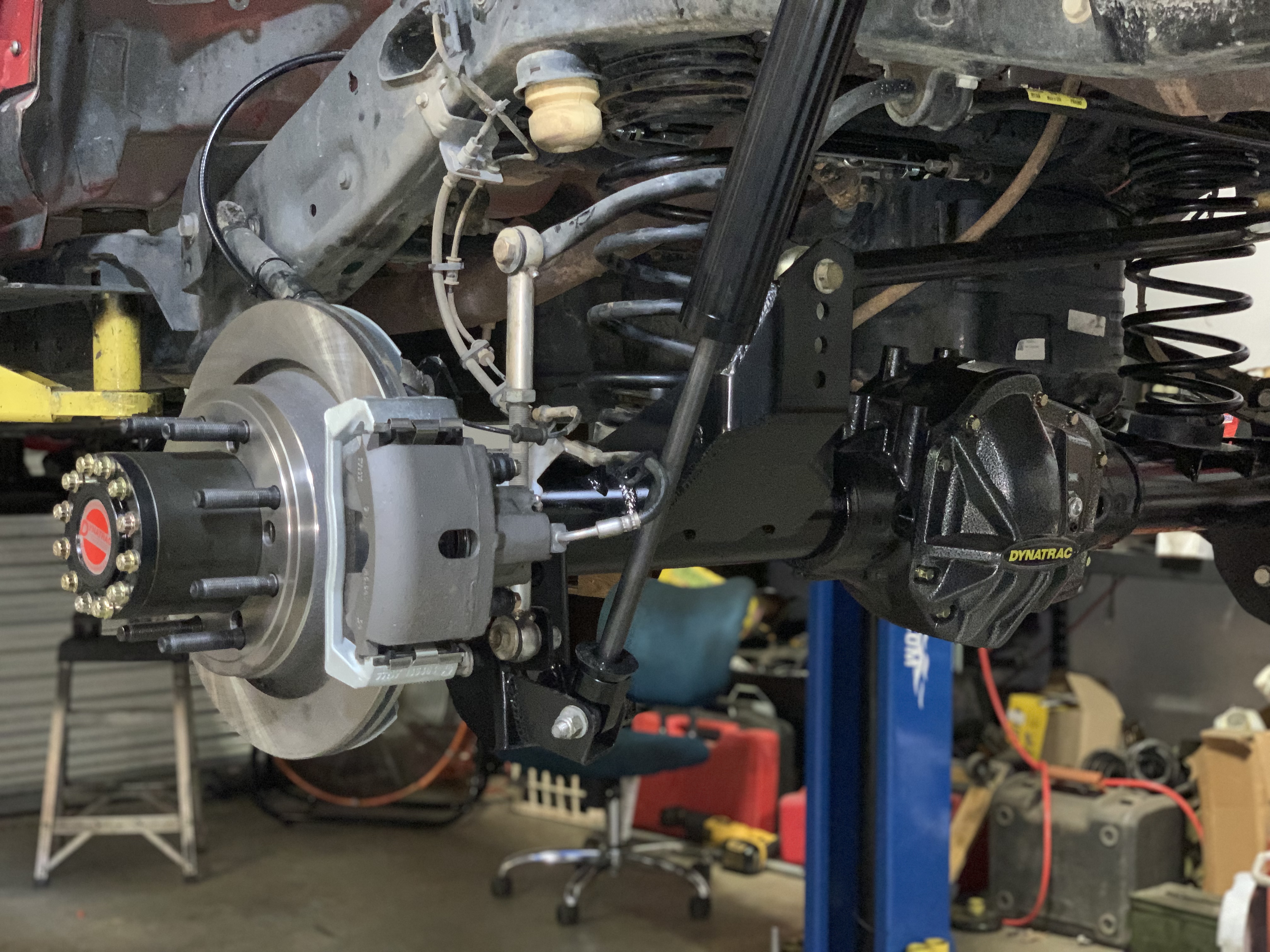

Not even kidding when I say this: When the Dynatrac axle set was installed in my Jeep by Off-Road Mafia, they dropped the old axles out, and bolted the new axles in to all of my Rock Krawler control arms, hooked up three connections to the ARB air locker to my sPOD Bantam and bolted in new driveshafts from Adam’s Driveshafts and aligned it, and that was pretty much it. My stock brake lines are still even attached to these axles.

My old axles had over 37,000 “smiles by BOB”, completely stock with the exception of, the Steer Smarts YETI XD Steering and a couple raised Trackbar brackets. The rest of the components…well…let’s just say it was time for the upgrade. After rolling out of Offroad Mafia on freshly installed Dynatrac XD60 axles, as well as adhering to the break-in period, I drove the Jeep for about 15 hours over the next couple days without a single issue. I didn’t even have to turn the radio up louder to silence bad noises!

junkyard vs. bolt on One-Ton Axle Swaps. It’s a heated debate – which way should people go?

I’ve owned keys to Jeeps with both, so here’s what I’ll say:

When it comes to junkyard one-ton swaps, bolting stuff together and driving out of the shop is a bit more challenging. Junkyard one-ton swaps in a Jeep will teach you all the awesome things you need to know about how to make a vehicle from a totally different year, make and model, drive properly with axles out of a Ford or Chevy truck. You’ve got to take into consideration things like: tone rings, ABS sensors (dodge ABS sensors vs. factory ones), different brake calipers, different brake pads, different brake lines, etc. You have to account for EVERYTHING, because you’re rebuilding an axle housing end to end from scratch with all new brackets and internals. Taking a front axle out of a 2006 Ford F-350 and a rear 14 Bolt axle from a Chevy Truck and putting it into a 2018 Jeep Wrangler with a welded-on Artec Industries swap kit is a satisfying project to complete and you’ll appreciate what you just did. It takes a good amount of knowledge, a really good welder, some late nights, and A LOT of pizza…I do like pizza. People do it all the time, I’ve wheeled with plenty of Jeepers running their own home built setups. With that being said, this time around, choosing a 100% bolt-in setup like a Dynatrac XD60/60 Combo, all I had to do is break the crate open and Off-Road Mafia had the Jeep done in just a few days.

Honestly, going with the bolt on route saves a lot of time. It’s worry free because you know once the new axles are in, they have been 100% purpose built for the Jeep Wrangler platform, engineered to give you the strength of a one-ton truck axle, certified and ran through a quality control department to check for the smallest imperfections. Junkyard swaps are a great option for the builder types–the guys who want to be cost-effective, but are also interested in tinkering with the axle components and using whatever mounts and brackets they choose. That’s where you can take a junkyard axle and make it brand new again. But with the bolt on stuff, all you have to do is open the box and install them. Maybe one day I will learn to weld and engineer my own suspension, but for now I’ll be happy with the Dynatrac setup paired with the Rock Krawler Suspension.

So you immediately took your new install out of the shop and drove it for 15 hours. What did you notice from your “Butt Dyno,” what changed in your ride, how did things feel, etc.?

Okay so for starters, new axles means new gear ratio, new experience! I finally have correct gearing in my Jeep. I am running a Jeep Wrangler that is Ripp supercharged on 40” tires and now I have a 5:13 gear ratio instead of the stock 4:10 gearing. So this means I’m able to see 7th & 8th gear again as well as get more smiles per gallon. Second, the braking and handling of the Jeep is much improved with larger rotors and a wider stance. Overall my favorite part is having a 5:13 gear ratio for the bigger tires. Everything is pre-installed and hand built over at Dynatrac in Huntington Beach, CA. I’ve got peace of mind again and one well built Wrangler to continue taking me anywhere in the country that I choose!

final thoughts?

As I mentioned, I’ve done both types of axle swaps. In 2017 I had a great opportunity to learn and help build the junkyard tons in my old Jeep JKU. They were nice, but they weren’t Dynatrac. I opted for Dynatrac with this new JL build because, for me, it’s one of those things I have strived for in a Jeep build. I have ran Jeeps really hard the past few years and to have these Dynatrac axles underneath my Jeep now, I can finally say I’m done with it (for now). I have the perfect platform for the next 10 years on this Jeep if I want to.

There you have it, folks–the low down on Bob’s experience with Dynatrec’s one-ton axles. It sounds like his build is so much better because of this addition and we’re excited to see where else he takes his build knowing he’s got some of the best one-ton axles on the market. What do you think? Are you team junkyard or bolt on? Let us know in the comments below and be sure to check out Bob’s JL build @boblife365.